Learn about Swimming Pool Installation

Introduction and Project Outline

Outline:

– Define goals and budget

– Choose pool type, size, and features

– Assess site and secure permits

– Plan the build sequence

– Specify systems and safety

– Map costs, timeline, and maintenance

A swimming pool can turn a backyard into a mini resort, a training lane, or a quiet retreat. Its relevance reaches beyond leisure: outdoor living has gained traction in recent years as households invest in at‑home amenities, and a well-executed pool often enhances daily routines, social gatherings, and property appeal. However, a successful installation is a construction project first and a lifestyle upgrade second. That means feasibility, codes, soil conditions, water management, and maintenance need to shape your vision from day one. Clear planning streamlines approvals, reduces rework, and helps control costs throughout excavation, shell construction, plumbing, electrical, and finishing.

Set intentions early: lap training, family play, hydrotherapy, or entertaining each suggest different sizes, depths, and temperature targets. Typical residential pools range from about 12×24 feet for compact lots to 16×32 or 18×36 feet for multipurpose swimming, while dedicated lap pools often stretch 40 feet or more in length for comfortable strokes. Upfront costs vary with materials and site complexity: in many markets, in‑ground installations span roughly the mid‑five to low‑six figures, while above‑ground options can be a fraction of that. Timelines also range—days for above‑ground, several weeks for fiberglass, and two to three months or more for custom concrete—depending on weather, permitting, and subcontractor availability.

Safety and codes are non‑negotiable. Most jurisdictions require a barrier at least 4 feet high, self‑closing and self‑latching gates, compliant suction outlets, and ground‑fault protection for electrical components. Some areas also regulate setbacks from property lines, overhead lines, septic systems, and easements. From water chemistry to energy use, ongoing stewardship matters: pumps may consume hundreds to a couple thousand kilowatt‑hours per year, and good circulation, filtration, and balanced chemistry can protect finishes while saving time and money. With a grounded plan, your project advances from sketch to stakeout to swim in a steady, predictable arc.

Choosing the Right Pool Type, Size, and Features

Align the structure with your goals, budget, climate, and soil. Four broad categories cover most residential needs, each with notable traits:

– Concrete (shotcrete or gunite): Highly customizable in shape, depth transitions, and integrated features. Durable, repairable, and well‑suited to sloped sites or complex designs. Generally higher cost and longer build time. The interior finish (plaster or pebble aggregate) typically needs resurfacing every 10–20 years depending on care and water balance.

– Fiberglass: A factory‑molded shell with a smooth gelcoat surface. Fast installation, low porosity, and pleasant underfoot feel. Size and shape are limited to what can be transported, and careful leveling/backfill are critical to avoid shell stress. The smooth surface can reduce routine brushing and may help limit chemical consumption when circulation and chemistry are well managed.

– Vinyl‑liner: Lower upfront cost and a cushioned surface, with modular wall systems that allow many footprints. Liners usually require replacement in 7–12 years, and puncture protection is a consideration near sharp objects or pet claws. Upgrades like thicker liners and protective floor pads can extend life.

– Above‑ground: The quickest path to a swim, with modest site prep and a compact budget. Lifespan is typically shorter than in‑ground structures, and aesthetics rely on creative decking, landscaping, and screening. Codes still apply—barriers, steps, and electrical safety must be addressed.

Pick dimensions with purpose. Families often prefer a shallow‑to‑mid-depth profile (around 3.5 to 5.5 feet) for play and lounging, while fitness‑minded owners may target a straight‑wall rectangle with at least 40 feet of length and consistent depth to reduce turbulence. True diving requires an engineered deep end (often 8–9 feet or more) and compliant slopes; many modern designs favor sport bottoms or uniform shallow depths to maximize usable area and simplify heating.

Features should serve how you swim and relax:

– Tanning ledges and bench seating add multi‑use zones without enlarging the footprint.

– Automatic covers improve safety, heat retention, and debris control, but require compatible track systems and clearances.

– Heaters (electric heat pumps, solar panels, or gas units) extend the season; pairing a cover with efficient setpoints often yields the biggest savings.

– Decking materials—poured concrete, pavers, or natural stone—affect heat underfoot, slip resistance, and maintenance.

– Lighting enhances evening use and safety; ensure low‑voltage, outdoor‑rated fixtures with proper bonding and protection.

In colder climates, freeze‑thaw cycles, frost depth, and winterization drive details like wall materials, plumbing depth, and drainage. In hot, sunny regions, consider shading, prevailing winds (which accelerate evaporation), and finishes that resist UV and scale. A well‑matched design feels intuitive: circulation is balanced, traffic flows easily, and the water invites you in the moment you step outside.

Site Assessment, Permits, and Groundwork

A thoughtful site assessment prevents expensive surprises. Start by locating underground utilities with your local utility‑marking service (commonly a “call before you dig” hotline, such as 811 in the U.S.). Confirm property lines, easements, and setbacks with a current survey. Many municipalities require separation from structures, septic components, and wells; overhead clearance from power lines is also regulated. Drainage is crucial: the pool should sit high enough to divert stormwater, with the deck sloped (often around 1–2%) to drains that route runoff away from the shell and house.

Observe sun, wind, trees, and sightlines. Southern and western exposures warm water naturally; windbreaks reduce evaporation and heat loss; mature trees offer welcome shade but shed leaves and pollen. Pay attention to slopes—significant grade changes may require retaining walls, stepped decks, or over‑excavation and engineered backfill. In areas with high water tables, include hydrostatic relief and under‑drainage; a sump line can protect the shell when the pool is empty for maintenance.

Permitting typically involves building, electrical, and plumbing permits, plus approval of a barrier plan. Review fencing height, gate hardware, latch height, and alarm requirements early to avoid rework. Neighborhood associations may add aesthetic or placement rules. Permit timelines vary widely—two to eight weeks is common—so parallel‑path your design and equipment selections while the application moves through review.

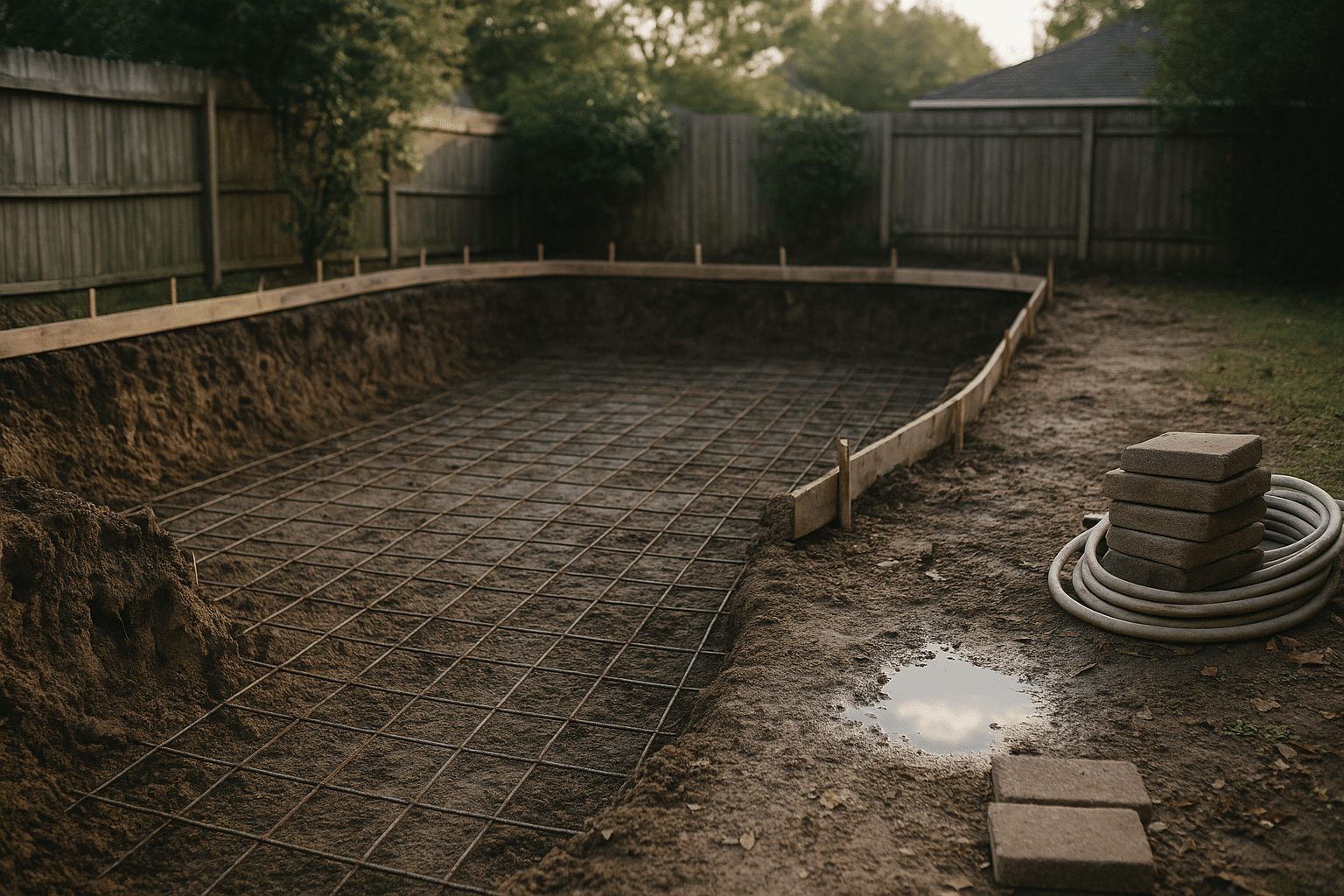

Groundwork begins with layout and excavation. The dig usually extends beyond the finished waterline to allow for forms, plumbing runs, and decking. Soils matter: sandy sites need attention to slope stability; expansive clay demands uniform moisture control and well‑compacted bases; rocky ground slows production and can increase hauling costs. Consider specifying:

– Compaction standards for base and backfill (verified with density tests where appropriate).

– Washed gravel or crushed stone bedding for drainage, especially under fiberglass shells.

– Geotextiles to separate soils and aggregate in problematic conditions.

– Temporary dewatering measures if seepage is present during excavation.

Before concrete or shell placement, the inspector will often verify steel, bonding, and suction fittings. Plan staging: stockpile spoil if it will be reused for grading, or schedule timely haul‑off to keep the site efficient and safe. A tidy jobsite shortens the build and reduces damage to lawns, sprinkler lines, and neighboring properties.

Installation Steps: Structure, Plumbing, and Finishes

Concrete builds begin with a steel cage tied to engineered specs, commonly using a grid pattern with tighter spacing in high‑stress zones like transitions and steps. Plumbing for skimmers, returns, and cleaner lines is pressure‑tested before the shell is shot. Dual, properly spaced suction outlets with anti‑entrapment covers are a safety staple. After shotcrete or gunite placement, crews shape and trowel surfaces; curing is critical—light, frequent watering over the first week helps reduce shrinkage cracking. Many projects pause 7–28 days before interior finishes to allow the shell to stabilize.

Fiberglass installations set the factory shell on a laser‑leveled gravel bed. The crew checks diagonals and beam level, then fills the pool with water in sync with backfilling to equalize pressure and avoid distortion. Lateral supports, proper pipe bedding, and non‑expansive backfill materials protect the shell over time. Steps, benches, and ledges are integral, so accurate elevation control determines the final waterline and deck alignment. Attention to crane access, travel paths, and ground bearing capacity keeps the set precise and safe.

Vinyl‑liner pools assemble with steel or polymer wall panels anchored to a footing, braced at intervals, and connected with a coping track. The floor is shaped with a smooth, troweled base (often vermiculite‑cement or sand‑portland blends) to support the liner without telegraphing imperfections. Once the liner is hung and vacuum‑set to remove wrinkles, filling begins; careful water chemistry from day one protects seams and color.

Across all types, hydraulic design matters. Target a full turnover of water roughly once every 6–8 hours for typical residential use, adjusting for bather load and climate. Use sweeping elbows and adequately sized suction and return lines to reduce head loss and allow lower pump speeds. Equipment pads should be level, well‑drained, and accessible, with proper bonding and ground‑fault protection for pumps, lights, and outlets. Consider future service space for heaters, solar valves, or salt systems.

Finishes and decks unify the project. Waterline tile resists scale and staining; interior surfaces range from classic plaster to exposed aggregate for texture and longevity. Deck materials influence comfort and runoff; include a control‑joint plan and an expansion joint with elastomeric sealant where deck meets pool to accommodate movement. Start‑up procedures—brushing, filtration, and balanced chemistry—help surfaces cure evenly and look uniform. When equipment starts humming and water turns from cloudy to crystalline, the yard reads like a complete, intentional space rather than a construction site.

Operation, Costs, Maintenance, and Conclusion

Daily enjoyment rests on smart operation. A variable‑speed circulation schedule often trims energy while maintaining clarity: for example, low speed most hours with a mid‑day boost for skimming. Chemical balance protects finishes and bathers; common residential targets include free chlorine around 1–3 ppm, pH near 7.2–7.8, total alkalinity roughly 80–120 ppm, calcium hardness in the 200–400 ppm range, and cyanuric acid around 30–50 ppm for stabilized chlorine systems. Saltwater generators automate chlorine production with typical salinity in the low thousands of ppm; they still require regular testing, cell cleaning, and pH control.

Filtration options carry distinct maintenance rhythms:

– Sand filters: Simple and durable; backwash when pressure rises 8–10 psi.

– Cartridge filters: Fine filtration without backwashing; clean cartridges periodically and replace as needed.

– Diatomaceous earth filters: Very fine clarity; more steps to recharge media after backwashing.

Expect ongoing costs in three buckets—energy, chemicals, and service/repairs. Many households see electricity for pumps and, if used, heaters ranging from modest seasonal amounts to notable monthly line items, depending on runtime, climate, and equipment efficiency. Chemical costs vary with sunlight, bather load, and rain; consistent dosing avoids expensive corrections. Seasonal tasks such as opening, closing, and cover maintenance can be done DIY with checklists or outsourced for predictable fees. Robotic cleaners, while an extra purchase, can reduce manual vacuuming and stir circulation dead spots.

Safety upgrades are wise investments: a code‑compliant fence and gate, alarms where required, anti‑slip deck surfaces, and clear depth markings. Keep suction fittings intact and never operate the system with broken covers. Store chemicals safely, pre‑dissolve where advised, and dose with the pump running for even distribution. Document equipment models, valve positions, and start‑up procedures in a binder or cloud note for quick reference.

Conclusion and next steps: Begin with a written brief—purpose, must‑haves, nice‑to‑haves, budget ceiling, and target completion date. Walk the yard at different times of day to read sun, wind, and privacy. Interview qualified contractors, ask for detailed scopes, and compare apples to apples on structure thicknesses, steel schedules, plumbing sizes, and warranty terms. A pool rewards thoughtful planning: when design, soil, hydraulics, and safety align, you gain a calm, inviting water space that fits your life—and keeps its sparkle season after season.