Learn about Swimming Pool Installation

Outline and Big‑Picture Roadmap

Installing a swimming pool is part construction project, part lifestyle upgrade, and part long‑term investment. A clear outline keeps the process predictable and reduces surprises. Before you break ground, sketch the journey from concept to first swim. Here is a concise roadmap you can tailor to your property and priorities:

– Vision and goals: clarify the why, who will use it, and how often

– Site analysis: sun, wind, slope, soil type, drainage, and privacy

– Budget and financing: total project envelope, reserves, and cost controls

– Design choices: pool structure, size, depth profile, decking, and features

– Compliance: permits, inspections, safety barriers, and utility locates

– Build sequence: excavation, shell, plumbing, electrical, and finishes

– Equipment: circulation, sanitation, heating, lighting, and automation

– Startup and training: water balancing, cleaning routines, and warranties

– Maintenance plan: seasonal tasks, service options, and lifecycle costs

This outline matters because a pool touches many parts of a property. Sun drives water temperature and evaporation. Wind influences heat loss and debris. Slope and soils affect excavation difficulty and structural needs. Local rules set minimum distances from property lines, septic systems, or overhead lines. A realistic budget prevents corner‑cutting that might cost more later.

Timeframes vary by design and region, but a common in‑ground schedule spans 6 to 12 weeks once permits are approved. Fiberglass shells often install faster (sometimes in 1 to 3 weeks after delivery) because the structure arrives pre‑formed. Concrete pools take longer due to forming, steel, and cure times. Vinyl‑liner pools usually fall in the middle, depending on site complexity and decking choices. To keep momentum, align inspections with milestones, pre‑order long‑lead items, and confirm utility markings well before excavation.

Two practical tips anchor every successful installation: plan for change, and measure twice. Include a 10 to 15 percent contingency within your budget and timeline for surprises like rocky soil or weather delays. Use scaled drawings and stakes to confirm layout in real space; a tape measure walk‑through often reveals issues with furniture clearance, gate swing, or sightlines you won’t see on paper. With this roadmap, you can approach each decision deliberately, avoiding costly improvisation on the jobsite.

Site Selection, Design, and Permitting Essentials

Choosing where the pool goes is as consequential as choosing the pool itself. Start with solar exposure: more direct sun means warmer water and potentially reduced heating costs. As a rule of thumb, aim for at least 6 hours of sun in peak season on the main swim area. Wind breaks such as hedges or fences can curb heat loss and keep debris out. Consider privacy from neighboring windows and second‑story vantage points; a few degrees of orientation adjustment can improve comfort and reduce the need for tall screens.

Topography and soils dictate excavation difficulty and structural approach. Flat or gently sloped sites simplify construction. Steep grades may require retaining walls or stepped decking. Sandy soils drain quickly but can cave during excavation without proper shoring. Dense clays are stable but may expand and contract with moisture, requiring careful compaction and backfill management. In areas with a high water table, hydrostatic relief or under‑drains help prevent buoyancy issues in empty or partially drained pools.

Map every underground and overhead constraint before digging. Use your regional utility‑locate service to mark communications, gas, water, and power lines. Keep clear of septic tanks and leach fields as mandated by local codes. Respect easements and drainage paths; altering runoff can create downstream problems, including erosion or water pooling against foundations. When in doubt, consult a civil or geotechnical professional for slope stability and drainage strategies.

Permits and approvals protect both safety and resale value. Expect to submit a site plan, pool drawings, equipment specs, and barrier details. Typical requirements include:

– Setbacks from property lines and structures

– Bonding and grounding for metallic components

– GFCI protection for receptacles and underwater lighting

– Barriers: fences of a specified height (often 48 inches or more), self‑closing gates, and door or surface alarms where applicable

– Anti‑entrapment features for drains and suction points

Thoughtful design merges compliance with comfort. Depth profiles might include a 3.5‑ to 4‑foot play zone and a deeper area for exercise. Steps, benches, and handholds improve accessibility. Plan circulation around the pool: at least 4 feet of clear deck is workable, while 6 to 8 feet supports lounge furniture and traffic. Choose surface textures that remain slip‑resistant when wet. If you anticipate a future spa, fire feature, or outdoor kitchen, stub in utilities now to avoid tearing up finished work later.

Choosing Pool Structures, Materials, and Equipment

Three in‑ground structures dominate residential installations, each with a distinct balance of cost, speed, and customization.

Vinyl‑liner: A modular wall system supports a flexible vinyl membrane. Advantages include a smooth, comfortable finish and a relatively lower upfront cost. Shapes are versatile, and installation timelines are moderate. Over time, liners typically need replacement (often in 7 to 12 years), and owners must manage water chemistry to avoid premature wear. Sharp objects and pet claws can puncture if not managed carefully.

Fiberglass shell: A one‑piece factory‑molded basin arrives ready to set. These are renowned for sleek interiors and quick installation; many projects go from excavation to water in a few days once the shell arrives. The nonporous surface can be easy to clean and resist staining. Size and shape options are curated rather than unlimited, and access challenges (tight side yards, overhead lines) can complicate delivery. Base preparation and level control during setting are critical to avoid shell stress and settlement.

Concrete (shotcrete or gunite): This custom‑formed structure offers nearly unlimited shapes, tanning ledges, beach entries, and deep ends. It suits complex sites and high‑end detailing. The tradeoff is a longer timeline due to forming, steel placement, spraying, and curing. Surface finishes range from white plaster to quartz and pebble aggregates. Periodic resurfacing may be required (often 10 to 15 years for plaster, longer for certain aggregates), and water chemistry discipline remains important to protect finishes.

Equipment choices define how the pool runs day to day. Circulation pumps with variable‑speed motors can reduce energy use significantly compared with single‑speed units by operating at lower RPMs for longer periods. Filtration options include:

– Sand filters: simple to operate, effective for larger debris, backwash required

– Cartridge filters: fine filtration, water‑conserving, periodic cartridge cleaning

– Diatomaceous earth filters: very fine filtration, more maintenance steps

Sanitation pathways vary. Traditional chlorination remains reliable and widely supported. Saltwater systems generate chlorine from salt in the water, providing steady levels with a soft feel; electrodes need periodic replacement. Supplemental systems such as ultraviolet or ozone can reduce the amount of sanitizer required, but still rely on a residual disinfectant in the water for complete coverage.

Heating choices depend on climate and usage. Heat pumps offer efficient temperature maintenance in moderate conditions, often with a coefficient of performance that outpaces combustion heaters when ambient air is mild. Gas heaters raise temperature quickly, appealing for spot heating and shoulder seasons. Solar heating and solar covers are passive strategies that can extend the season and reduce fuel costs, especially in sunny regions. Lighting, automation, and safety covers round out the package; choose components that are serviceable and supported locally to simplify long‑term ownership.

Step‑by‑Step Installation Process and Realistic Timeline

Every build is unique, but the sequence below captures the major milestones. Planning and mobilization begin after permits are in hand and utility markings are visible on site. A pre‑construction walkthrough confirms pool layout, finished elevations, and access routes for equipment and materials. Photograph existing conditions and adjacent structures for reference.

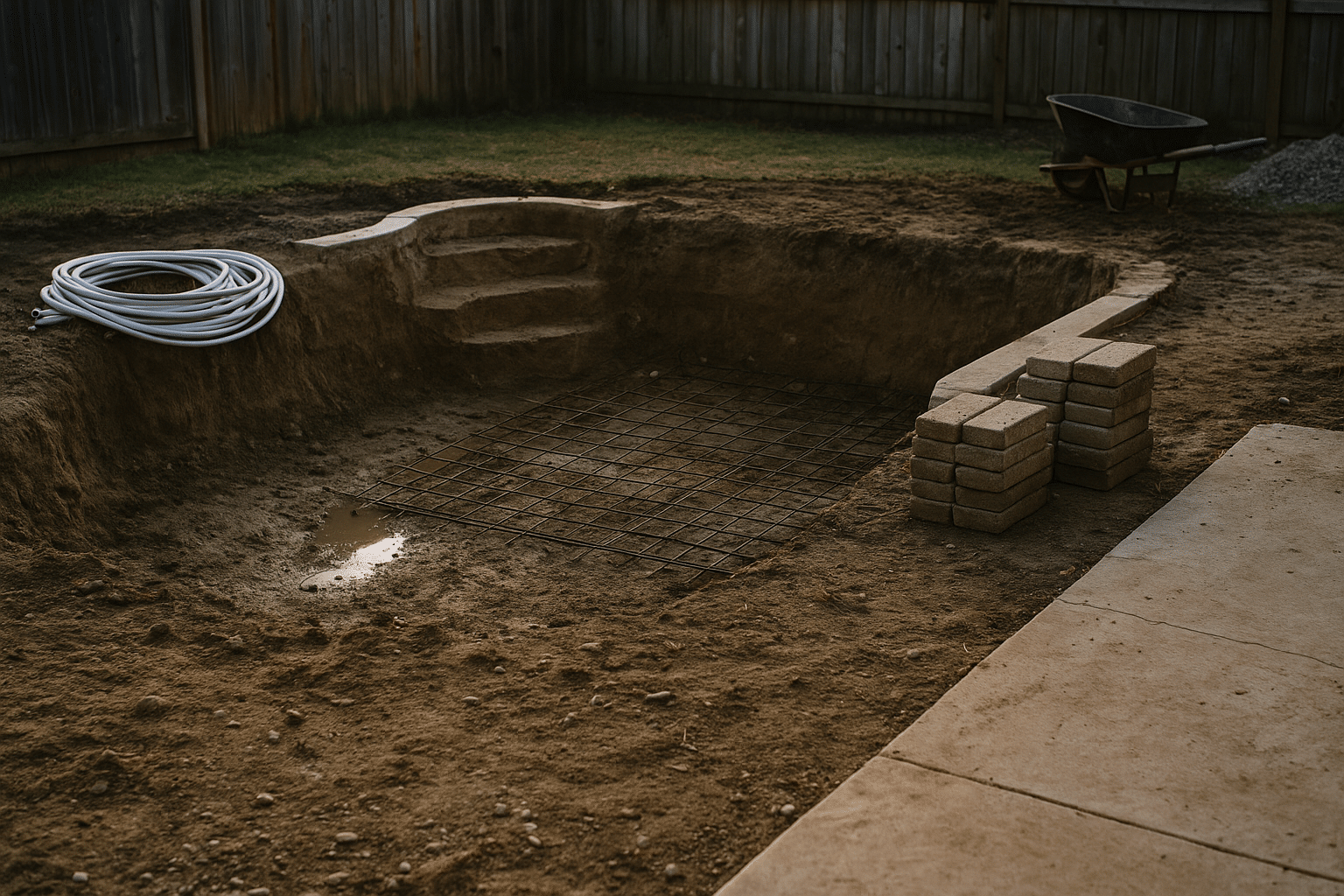

Excavation: Crews dig to the design shape plus over‑excavation for base material. Spoils are either hauled off or reserved for grading. In wet or unstable soils, temporary shoring or dewatering may be required. Base prep follows: compacted gravel beds are common; vinyl‑liner floors may use a smooth vermiculite or cementitious mix; fiberglass shells benefit from uniform bedding to prevent point loads.

Structure installation: For fiberglass, cranes or lifts set the shell into the excavation while teams verify level in multiple axes. Simultaneous water filling and backfilling help equalize pressure and avoid distortion. Vinyl‑liner pools assemble wall panels and braces before floor finishing and liner placement; vacuum systems draw liners tight for a precise fit as filling begins. Concrete pools progress through steel reinforcement, plumbing rough‑in, and the shotcrete or gunite application. After shooting, the shell cures; the duration varies with climate, but planners often allow two to four weeks before finish coats.

Plumbing and electrical: Install suction lines, returns, skimmers, cleaner lines, and any water features. Pressure tests verify integrity before backfill. Electrical work includes bonding of metallic components, grounding, and protective devices for outlets and lighting. Coordinate inspections at each stage; passing early checks prevents costly rework later.

Decking and hardscape: Forms define the deck pour for concrete, or the base is compacted for pavers. Expansion joints and control joints mitigate cracking. Coordinate drainage to direct water away from structures and toward approved discharge points. Edging, coping, and steps are finalized here, setting the tone for both safety and aesthetics.

Interior finish and startup: Plaster, quartz, or pebble finishes are applied to concrete pools, often followed by an immediate fill to prevent cracking. Fiberglass interiors need careful water balancing to protect the gelcoat. Vinyl liners require gentle startup to preserve seams. Balance water to commonly recommended ranges: pH around 7.2 to 7.8, total alkalinity roughly 80 to 120 ppm, and calcium hardness in the 200 to 400 ppm range depending on finish. Initial brushing, filtration, and staged chemical additions help the system stabilize over the first week.

Timelines: With all materials ready and no weather or inspection delays, a fiberglass project might wrap in 1 to 3 weeks after delivery; vinyl‑liner in 3 to 6 weeks; concrete in 6 to 12 weeks. Add lead time for permits, design revisions, and site complexities. A written schedule with milestones, inspection dates, and payment points keeps everyone aligned from dig day to first dip.

Budget, Maintenance, Safety, and Conclusion for Homeowners

A complete budget includes more than the shell. Typical ranges vary by region and design, but many in‑ground projects land in the tens of thousands of dollars. Concrete builds generally sit at the higher end due to labor and finish work; fiberglass and vinyl‑liner installations can be more modest depending on site conditions and decking choices. Don’t forget essentials outside the pool: fencing, gates, electrical upgrades, soil haul‑off, and landscaping can add materially to the bottom line.

Planning tips:

– Keep a 10 to 15 percent contingency for surprises such as rock excavation or drainage fixes

– Break costs into phases: design and permits, excavation and structure, utilities, decking, finishes, and accessories

– Compare life‑cycle items: liner replacement, plaster resurfacing, or periodic refinishing for fiberglass gelcoats

– Consider operating costs: electricity for pumps and heaters, chemicals, periodic service, and winterization in cold climates

Annual ownership costs depend on climate and pool size. Energy use varies with pump type and runtime; longer, slower filtration cycles with efficient pumps can reduce consumption compared with short, high‑speed operation. Chemical costs fluctuate with bather load and sunlight. A simple maintenance plan—skimming, brushing, filter cleaning, and weekly testing—prevents small issues from becoming repairs. Professional service is an option for those with limited time; ask for written scope and seasonal checklists to compare providers fairly.

Safety is non‑negotiable. Most jurisdictions require a barrier at a specific height with self‑closing, self‑latching gates. Door or surface alarms may be needed if the house forms part of the barrier. Choose anti‑slip deck textures and handrails where appropriate. Drain safety covers that meet current standards reduce entrapment risk. Lighting improves night visibility. Keep a reaching pole and a life ring accessible, and establish family rules for diving, running, and supervision.

Sustainability and comfort can align. Solar covers cut evaporation, heat loss, and chemical consumption. Shade structures lessen UV degradation of finishes and reduce cooling needs in hot climates. Variable‑speed pumps and smart controls help dial in efficient runtimes. Planting windbreaks and drought‑tolerant landscaping eases water use while creating a calm microclimate around the pool.

Conclusion for homeowners: A pool succeeds when it matches how you live, not just how it looks on a plan. Start with a realistic budget, choose a structure that fits your site and climate, and insist on clear milestones for permitting, inspections, and construction. Build safety into the design from day one and set aside time for routine care. With thoughtful planning and disciplined execution, your pool becomes a reliable, year‑round asset for relaxation, play, and connection at home.