Learn about Swimming Pool Installation

Project Outline and Planning Roadmap

Installing a swimming pool blends construction, landscaping, budgeting, and long-term homeownership planning. Before a shovel hits the soil, it pays to sketch a clear roadmap. Here’s a practical outline of the topics this article develops in depth and how they fit together, so you can navigate decisions with confidence and avoid costly missteps.

– Vision and purpose: determine how you’ll use the pool—fitness laps, family play, or quiet lounging—informs size, depth, and features.

– Site analysis: evaluate sun exposure, slope, soil type, access for excavation, drainage paths, and nearby trees or structures.

– Codes and permits: confirm setbacks, barrier rules, and utility clearances; plan inspections and approvals.

– Design and materials: compare concrete, fiberglass, and vinyl options for durability, maintenance, and customization.

– Step-by-step build: understand excavation, shell installation, plumbing/electrical, backfill, decking, and startup.

– Budget and ownership costs: forecast installation totals, monthly energy, chemicals, water, and periodic resurfacing or liner replacement.

Anchoring the project in purpose is surprisingly powerful. A family focused on play may prefer a 15×30-foot pool with a shallower profile and wide entry steps, while lap swimmers might prioritize a longer, straight run with unobstructed lanes. Features like tanning ledges, benches, and integrated spas can enhance usability but add complexity, time, and cost. Early clarity prevents scope creep and change orders.

Site conditions are equally pivotal. A flat, easily accessible yard with loamy soil speeds excavation and reduces the need for retaining walls. A steep slope, hard bedrock, or a high water table may require over-excavation, dewatering, or engineered structures. Access matters too: if the gate is too narrow for machinery, expect more labor and longer timelines. Drainage planning, from yard grading to deck slopes, directs water away from the pool and your home’s foundation, protecting both.

With a roadmap in hand, your conversations with designers and contractors become sharper. You’ll prioritize must-haves over nice-to-haves, align the design with local codes, and schedule with realistic buffers for weather and inspections. The result is a project that feels less like a leap of faith and more like a measured, well-managed investment in outdoor living.

Site Selection, Codes, and Permits

A great pool starts with a great location. Sunlight keeps water warmer and reduces heating needs; wind exposure increases evaporation and chemical use. In many climates, south or west-facing placements maximize warmth, while planting windbreaks or using privacy fencing can tame breezes. Consider sightlines from the house: being able to view the pool from main rooms improves safety and makes the space feel connected to daily life.

Local codes govern where and how a pool can be built. Setbacks from property lines often range from roughly 4 to 10 feet, though specifics vary by municipality. Overhead power lines, underground utilities, and easements impose additional clearances. Before digging, call the utility locating service in your area to mark lines; hitting a utility is dangerous and expensive. Most jurisdictions require a barrier with self-closing, self-latching gates, and some specify alarms or safety covers. Permits typically cover structural, electrical, and sometimes plumbing work, with inspections at key stages such as steel/rebar, bonding, and final.

– Zoning checks: verify setbacks, height limits for fencing, and deck coverage.

– Soil and drainage: request a soil review if you suspect expansive clay or high groundwater; plan French drains or sump points where needed.

– Access logistics: confirm equipment can enter without damaging fences or irrigation; plan temporary removals if necessary.

– Neighbor considerations: communicate early about noise, dust, and delivery schedules to maintain goodwill.

Beyond compliance, think about safety and convenience. Place the equipment pad near the pool but far enough from windows to reduce pump noise. Keep the pad accessible for maintenance and sized to allow future upgrades. Lighting and GFCI-protected outlets around the yard support evening use and cleaning tools. If you intend to add a spa, solar heating, or an automated cover later, pre-run conduits and stubs now; it’s far less invasive than trenching through finished decking.

Timewise, permitting can take anywhere from one to eight weeks depending on local workloads and whether design revisions are needed. Build this into your calendar. Starting with a thorough site plan—dimensions, elevations, drainage strategy, and barrier details—helps minimize back-and-forth and accelerates approvals. A strong start here sets a smooth path for the rest of the build.

Choosing a Pool Type and Materials: Concrete, Fiberglass, or Vinyl

Pool structure is the backbone of the project, shaping cost, timeline, look, and long-term upkeep. Three primary types dominate residential builds: concrete (often shotcrete or gunite), fiberglass shells, and vinyl-liner pools. Each brings trade-offs worth weighing against your priorities, climate, soil, and budget.

Concrete offers virtually unlimited shapes, depths, and custom features like vanishing edges, raised walls, or integrated benches. It is robust and adaptable to complex sites. Typical installation timelines run longer due to curing, finishing, and more on-site work. Surface finishes vary—from standard plaster to quartz or pebble aggregates—with different textures and lifespans. Many owners resurface every 10–15 years, depending on water chemistry and care. Installed costs commonly start in the mid-five figures and can climb into six figures with elaborate designs and hardscapes.

Fiberglass shells arrive pre-molded in set shapes and sizes, which speeds installation and yields a smooth, low-porosity surface that’s easy to maintain. Limits on size and shape are defined by shipping constraints and the manufacturer’s molds, but there is a wide range of family-friendly layouts. Because the surface resists algae, chemical use and brushing time can be modest compared to rougher finishes. Gelcoat longevity is strong when water balance is maintained, and repairs, while specialized, are typically localized. Installed costs often fall in the mid range, with many projects landing between those of vinyl and larger custom concrete builds.

Vinyl-liner pools use a framed wall system with a custom liner that defines the interior. They offer design flexibility at a generally approachable upfront price. Liners commonly last 7–12 years before replacement, influenced by sun exposure, water chemistry, and physical wear. Wall and step options are more diverse than many expect, and liners come in a range of patterns and thicknesses. Upkeep centers on liner care—avoiding sharp tools, keeping chemistry balanced, and managing UV exposure. Installed costs typically trend lower than concrete, particularly for straightforward rectangles or modest freeforms.

– Maintenance profiles: smoother surfaces (many fiberglass finishes, some high-quality plaster) reduce brushing and can lower chemical demand.

– Energy considerations: modern variable-speed pumps often cut electric use roughly in half compared to older single-speed models, especially when paired with efficient plumbing.

– Climate fit: freeze-thaw cycles and expansive clays may favor certain structures or require specific engineering details.

– Resale: buyers value attractive, well-maintained pools with stable water quality and safe, code-compliant barriers more than exotic shapes with neglected finishes.

There is no one-size-fits-all answer. Concrete shines for artistic freedom and long-term robustness, fiberglass emphasizes speed and smooth maintenance, and vinyl balances affordability with customization. Match the structure to your use-case and site, and you’ll set yourself up for years of enjoyable, predictable ownership.

Step-by-Step Installation Timeline and What to Expect

Understanding the build sequence helps you plan around noise, deliveries, and the moment your yard transitions from dirt to blue water. Timelines vary, but many inground projects span 6–12 weeks under typical conditions, extending for complex sites, weather, or specialty features. Here’s how the process usually unfolds and what homeowners can do to keep it moving.

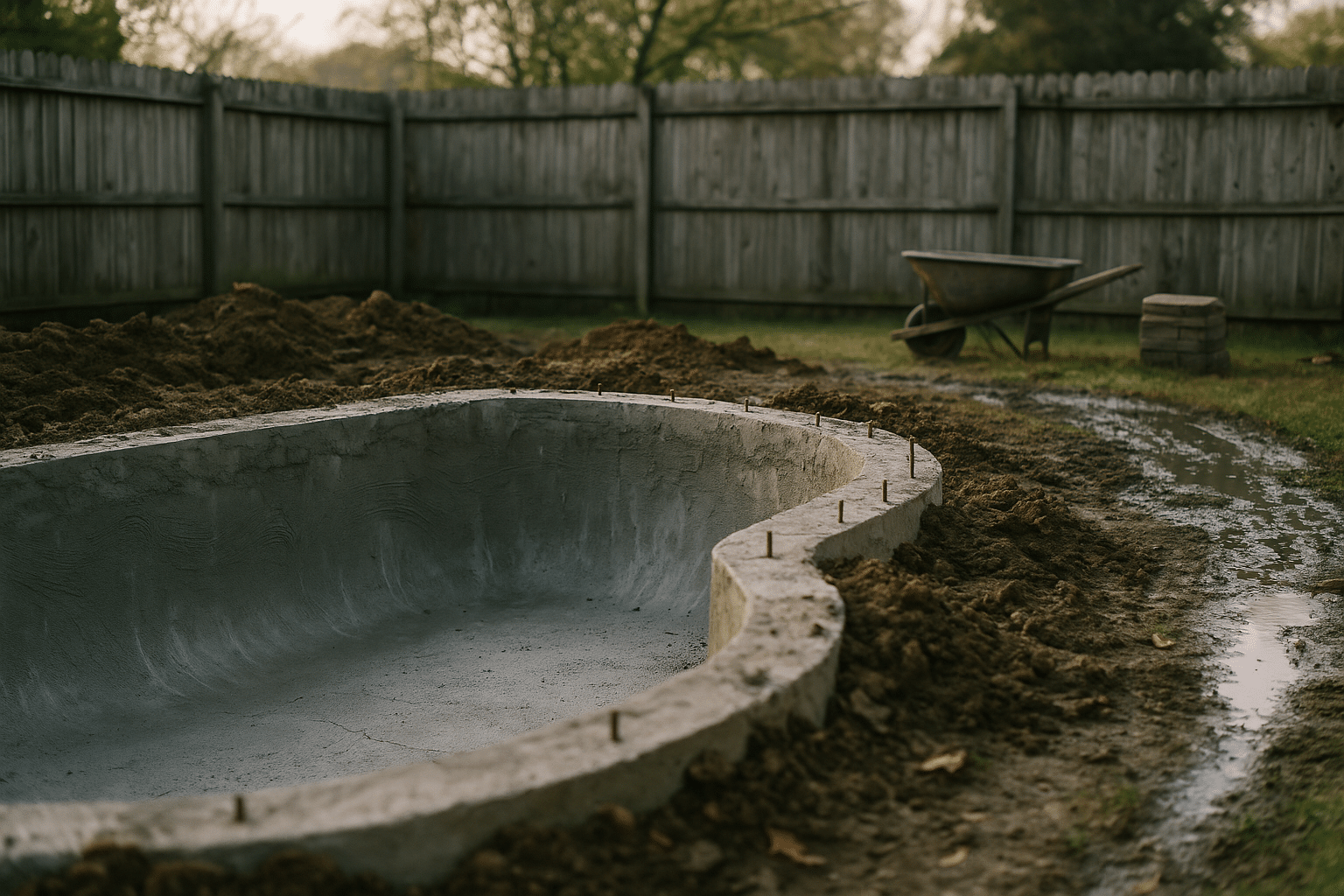

Layout and excavation: crews stake the outline, confirm elevations, and set access routes. Excavation depth includes the pool floor, plus extra for base material or over-excavation in weak soils. Expect soil piles and truck traffic; tarps and plywood can protect lawns and walkways. In rocky areas or high groundwater, plan for slower digging, dewatering pumps, or engineered solutions.

Shell construction:

– Concrete builds proceed with steel reinforcement, plumbing rough-ins, and shotcrete placement. After shooting, the shell cures while crews shape steps, benches, and features.

– Fiberglass shells are craned or guided into place on a prepared gravel base, leveled, and checked for correct elevations; water and backfill are added in lifts to keep pressure balanced.

– Vinyl projects set wall panels, pour a footing or collar, rough-in plumbing, and later stretch and lock in the liner once the floor is shaped and smoothed.

Plumbing and electrical: piping for returns, skimmers, main drains, water features, and future stubs runs to the equipment pad. Bonding the steel and water, and installing GFCI-protected circuits, is essential for safety and inspection approvals. Pressure testing ensures lines hold before the deck hides them. Equipment—pump, filter, heater or solar lines, sanitizer—gets mounted and plumbed, with valves labeled for clarity.

Decking and finishes: coping and deck forms go in, concrete or pavers are placed with slopes directing water away from the pool. In concrete pools, interior finishes (plaster, quartz, pebble) are applied near the end, followed by a careful fill. Fiberglass and vinyl pools transition to final set, trim, and decking more quickly, though weather can still slow progress. Landscaping and fences round out the space, with the final inspection verifying barriers, alarms, and safe operation.

Startup and handoff: the builder or service tech balances water, starts circulation, and walks you through testing, cleaning, and seasonal routines.

– Keep an owner’s log: water readings, chemical additions, and equipment settings help you spot trends.

– Inspect after storms: look for deck puddling, settlement, or loose hardware early, when fixes are simple.

– Plan a 30-day check: minor adjustments to timers, valves, or chemistry can refine efficiency and comfort.

Communication keeps surprises small. Ask for a written schedule, agreed working hours, and a contact for questions. Provide clear access, power, and hose water. With shared expectations, the site evolves from excavation to a finished retreat on a predictable arc.

Costs, Maintenance, and Conclusion: Making the Investment Work

Budgeting for a pool is about the full picture: install cost, ongoing ownership, and the value of more time spent outside. Installed prices reflect size, complexity, region, and site conditions. As a broad guide, many vinyl projects land in the lower-to-mid five figures, fiberglass in the middle tiers, and custom concrete can range higher, especially with large decks, walls, or water features. Add allowances for access repairs (replacing gates, sod, irrigation) and design extras like lighting or automation.

Ownership costs unfold monthly and seasonally. Electricity for pumps and heaters can add roughly $30–$90 per month, higher with long run times or electric heat. Chemistry varies with climate and pool surface but commonly falls in a few hundred dollars per season for chlorine or alternative sanitizing approaches, plus pH and alkalinity control. Water top-offs combat evaporation, and backwashing or filter cleanings keep clarity high. Every few years, plan for larger line items: a vinyl liner replacement, a new filter cartridge set, or eventual resurfacing for concrete finishes.

– Ways to manage costs: run a variable-speed pump longer at low speeds, choose a light-colored interior in hot climates to temper heat gain, and use a cover to reduce evaporation.

– Safety and compliance: functional gates, clear line-of-sight from the house, and good lighting matter as much as stylish tile.

– Durability tips: maintain balanced water, brush dead zones, and keep debris out of skimmers to reduce strain on equipment.

Financial returns are nuanced. A well-executed pool often enhances lifestyle and can support resale appeal in warm regions or neighborhoods where pools are common. Appraised value may not equal the full project cost, but marketability and time-in-use can bridge the gap. Think in terms of utility: if the household will use the pool frequently for years, the value proposition strengthens considerably.

Conclusion and next steps: define your purpose, document your site realities, and select a structure aligned with climate and budget. Request detailed quotes that itemize excavation, shell, equipment, deck, fence, and contingencies. Ask for a build schedule and inspection milestones in writing. With a grounded plan, you’ll trim delays, protect your budget, and step into the first swim with the confidence that the project was designed for how you really live—season after season.