Learn about Swimming Pool Installation

Outline and Big-Picture Planning

Before the first splash or even the first shovel, clarity is your strongest tool. In the spirit of a calm, well-lit lap lane, this article starts with an outline so you can see the full distance ahead. Here’s where we’re headed:

– Site Assessment, Permits, and Design

– Pool Types and Materials Compared

– Installation Step-by-Step: From Dig to Deck

– Costs, Timeline, Safety, Maintenance, and Conclusion

Use this as your map, particularly if you’re comparing quotes or scheduling contractors.

Big-picture planning means defining the purpose of your pool and the constraints of your property. Are you after family fun, fitness, or a tranquil water feature that anchors your landscape? Each goal nudges choices on depth, dimensions, and features. For instance, a lap pool benefits from uninterrupted straight runs (many swimmers find 12–15 meters workable in small yards), while a play-focused pool might include a shallow sun shelf, wide steps, or a sport-depth profile around 1.2–1.5 meters for water games. Aesthetics matter, but practical details like sun path, wind exposure, and neighboring windows impact comfort and privacy every day.

Think of your budget as both a fence and a foundation. It sets limits and keeps the project safe. A typical inground pool can range widely depending on materials, features, and regional labor costs. Upfront allowances for site work, utilities, decking, and fencing are essential, because the “pool” is only part of the final price. Time is another currency: permitting can take 2–6 weeks in many municipalities, and supply lead times may stretch project durations. By establishing clear goals, budgeting with a contingency (often 10–15%), and sequencing approvals early, you create an orderly build instead of a chaotic sprint.

Finally, choose how you’ll manage the project. A single prime contractor can simplify accountability, while a more hands-on approach—sourcing separate trades for excavation, shell, finishes, and decking—may save money but adds coordination complexity. Either way, confirm licensing, insurance, and references. A pool endures for decades; a careful start sets the tone for the water’s long, calm life in your yard.

Site Assessment, Permits, and Design

The ground beneath your feet is not just dirt; it’s a matrix of setbacks, utilities, soils, and water tables that will either cooperate or complain. Start with location intelligence: request utility locates, review your property survey, and note easements that can restrict placement. Check zoning for rear and side-yard setbacks, height limits for fences, and allowable impervious area. If your region has a high water table or sits near a floodplain, anticipate dewatering or engineered solutions. Sloped sites may need retaining walls or stepped decking, while clay soils benefit from drainage layers to mitigate expansion.

Permits safeguard both you and future owners. Local codes typically require structural plans, electrical layouts, barrier details, and sometimes drainage calculations. Expect inspections at multiple stages:

– Pre-excavation or layout verification

– Rough plumbing and pressure testing

– Electrical bonding and grounding checks

– Structural steel (for concrete shells) or set-and-backfill (for fiberglass)

– Final safety barrier inspection prior to filling

Plan for 2–6 weeks for permit review, though it varies by jurisdiction and season. Homeowners associations may require separate approvals and specific materials or colors for fences and decking.

Good design merges purpose with physics. For sunny comfort, locate the pool where it gets afternoon light but consider shade structures or planting for heat waves. Wind breaks reduce evaporation and heat loss. Place the equipment pad where it’s accessible, ventilated, and away from bedrooms to minimize pump noise. Think through circulation: skimmers should face prevailing winds, returns should promote thorough mixing, and vacuum lines or in-floor systems can simplify cleaning. Safety features are part of design, not afterthoughts: self-closing gates, compliant drain covers, proper suction configurations, non-slip coping, and clearly lit paths matter daily. Add a splash of personality with materials that relate to your home—stone that echoes your facade, pavers that match pathways, or tile that nods to garden tones. Create a space that feels inevitable, as if the yard was always waiting for water.

Pool Types and Materials Compared

Choosing the pool structure is like choosing a musical instrument: each type plays the same song—swimming—but with a different timbre, cost rhythm, and maintenance tempo. Four common options dominate residential yards: concrete (often pneumatically applied), fiberglass shells, vinyl-liner kits, and above-ground or semi-inground assemblies. Your climate, soil, design ambitions, and budget steer this decision.

Concrete (shotcrete or gunite) offers nearly unlimited shapes, steps, benches, and integrated features. It supports complex geometries, vanishing edges, and custom depths. Surface finishes range from plaster to exposed aggregate, each with a distinct texture and lifespan. Trade-offs include longer build times and higher labor intensity. In many markets, concrete inground installations may land in a wide range, reflecting custom design and finish choices. Maintenance centers on brushing to deter algae on the porous surface and periodic surface refinishing over the long term.

Fiberglass shells arrive pre-shaped, with smooth gelcoat interiors that feel comfortable underfoot and resist algae adhesion. Installation tends to be faster once the shell is on site, with backfill and plumbing proceeding quickly. The profile is factory-true, which helps waterline tile and coping align cleanly. Limitations include fewer shape options and transport constraints, but for homeowners who want durable surfaces with lower routine brushing, fiberglass can be highly regarded. Repair methods are specialized, and color-matching older gelcoats may require expert attention.

Vinyl-liner pools pair a structural wall system with a custom liner. Upfront costs can be attractive, and liners offer varied patterns and gentle feel. Expect a liner replacement cycle typically in the 7–12 year range depending on care and climate. While punctures are uncommon with sensible use, sharp objects and pet claws can be an issue. Structural floors and walls need careful compaction and vermiculite or foam bases to achieve smoothness. For many homeowners, vinyl strikes a compelling balance between design flexibility and budget awareness.

Above-ground or semi-inground options can deliver seasonal fun quickly. Modern kits offer stronger frames and attractive cladding, and some homeowners recess them partially for a more integrated look. Site leveling, pad preparation, and code-compliant fencing remain important. For families testing the waters before committing to a full inground build, this pathway can be a smart stepping stone.

Maintenance and energy considerations should weigh in:

– Surface porosity affects brushing frequency and chemical demand

– Darker interiors can feel warmer but show scale or fading more readily

– Integrated steps and benches add comfort but increase surface area to clean

– Saltwater chlorine generators simplify sanitization but still require water balancing

Ultimately, your lifestyle dictates the right ensemble: a minimal-maintenance fiberglass, a fully custom concrete sculpture, a budget-friendly vinyl canvas, or a fast-setup above-ground stage.

Installation Step-by-Step: From Dig to Deck

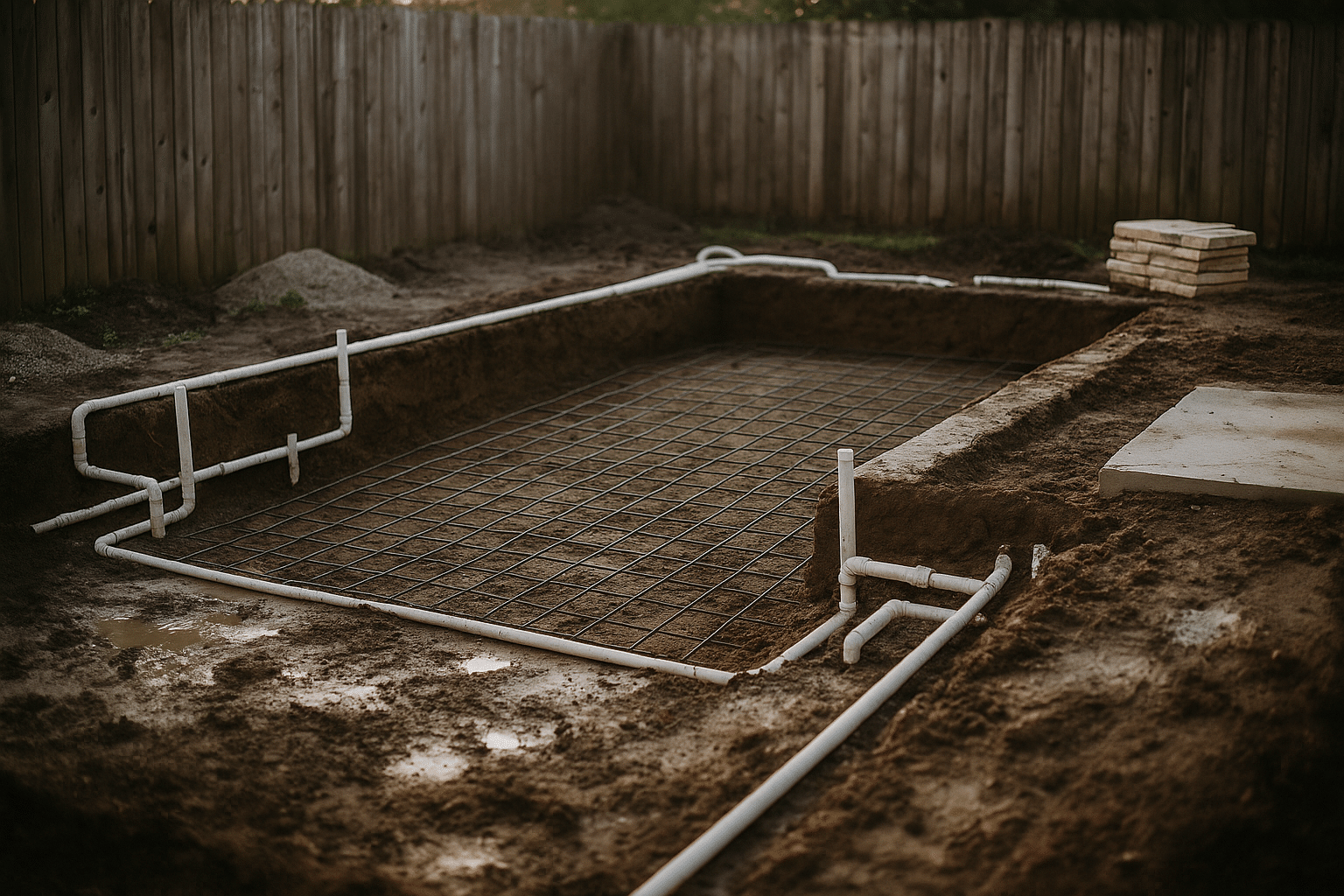

Construction follows a choreography that rewards patience and inspection. It begins with layout: stakes and strings set shape and elevations. Excavation removes soil to plan grade, allowing for base material and overdig where needed. Spoils are hauled off or reserved for backfill. The sub-base should be compact and true. For concrete pools, steel reinforcement follows—rebar grids and chairs—to create a rigid skeleton. Plumbing rough-in traces the pool’s arteries: skimmers, main drains (with compliant anti-entrapment covers and dual suction paths), returns, cleaner lines, and water features. Pressure testing verifies tightness before the shell is placed or shot.

Electrical and bonding integrate early. A bonding grid ties the pool structure, water, metal features, and equipment together to reduce stray voltage risks. Dedicated circuits feed the pump, lighting, and accessories, often protected by ground-fault devices where required by code. Conduit runs should be clean, with junction boxes elevated above waterlines and accessible for service.

The shell stage depends on type. Concrete pools receive shotcrete or similar material over rebar, then cure—often several weeks—before plaster or aggregate finish. Fiberglass shells are craned into place, checked for level, and backfilled with gravel while filling with water to balance forces. Vinyl projects set walls, pour collars, prepare the base, and hang the liner with careful vacuuming to remove wrinkles, then fill. Tile, coping, and waterline finishes bridge pool and deck. Decking—cast-in-place concrete, pavers, or stone—gets expansion joints and slopes set for drainage, ideally away from the water. Trim details, such as skimmer lids, return eyeballs, and cover tracks, finalize the edge.

Equipment commissioning turns a quiet basin into a living system. The pump priming, filter backwash, heater or heat pump checks, and controller setup come together. Lighting is tested at dusk to confirm beam spread and reflections. The initial water balance—pH, alkalinity, calcium hardness, sanitizer—sets the tone for surface health. Builders often provide a startup schedule that includes daily brushing (for new plaster), gradual chemical adjustments, and careful observation of pressure gauges. Typical inspection milestones include:

– Rough plumbing pressure test pass

– Electrical bonding verification

– Structural approval before finish

– Final barrier and safety inspection before full use

This measured sequence keeps surprises rare and ensures the pool is ready for years of steady laps and lazy floats.

Bringing It All Together: Costs, Timeline, Safety, and Long-Term Care

Budgeting for a pool means zooming out to see the whole picture—shell, site work, utilities, fencing, decking, landscaping, and permits. While regional prices vary, many homeowners organize budgets in these broad bands:

– Inground concrete: typically higher upfront, reflecting custom shapes and finish options

– Inground fiberglass: competitive installed pricing with faster timelines once delivered

– Inground vinyl-liner: often the most approachable entry point for a permanent pool

– Above-ground/semi-inground: the most economical path, with optional upgrades for decking and cladding

Add 10–15% contingency for rock excavation, drainage surprises, or design tweaks. Annual ownership costs can include water chemistry, electricity for pumps and heaters, seasonal service, and periodic surface care. Energy-savvy choices—efficient pumps, covers to curb heat loss, and thoughtful pump scheduling—trim ongoing expenses without sacrificing comfort.

Timelines hinge on permits, weather, and supply chains. A straightforward fiberglass project might complete in a few weeks once the shell arrives, while complex concrete builds can extend over several months due to curing and custom finishes. Vinyl-liner projects usually sit in the middle. To keep schedules predictable, align inspections early, approve selections before ordering, and authorize change orders sparingly and in writing. A simple rhythm helps: excavate, rough-in, shell, finish, deck, equipment, fill, balance, and final walkthrough.

Safety is non-negotiable. Most codes require:

– A barrier at least a specified height with self-closing, self-latching gates

– Compliant suction configurations and drain covers to reduce entrapment risk

– Proper bonding, grounding, and protected circuits for all electrical components

– Non-slip walking surfaces and clear lighting around the water

Add layers such as safety covers, door and gate alarms, and clear signage for depth transitions. Teach swimmers to respect the deep end, and store chemicals in ventilated, locked spaces away from heat and sunlight.

Maintenance keeps water clear and surfaces happy. A simple cadence works: skim debris, empty baskets, brush walls, vacuum as needed, and test water weekly. Balance pH and alkalinity first, then adjust sanitizer and calcium hardness. Shock after storms or heavy use, and clean filters when pressure rises per the manufacturer’s guidance. Seasonally, winterize in freezing climates and open methodically in spring. Keep records of readings and service—a tidy logbook reveals patterns early.

Conclusion: A pool is both a destination and a discipline. With thoughtful planning, careful type selection, orderly construction, and steady maintenance, you create a backyard water space that fits your routines and elevates everyday life. If you prioritize safety, budget with room to breathe, and choose features you’ll use often, your pool will feel like it belongs—quietly working with your landscape, not competing with it. Talk with licensed, insured professionals, compare detailed bids, and trust the process; the first ripple will be worth the preparation.